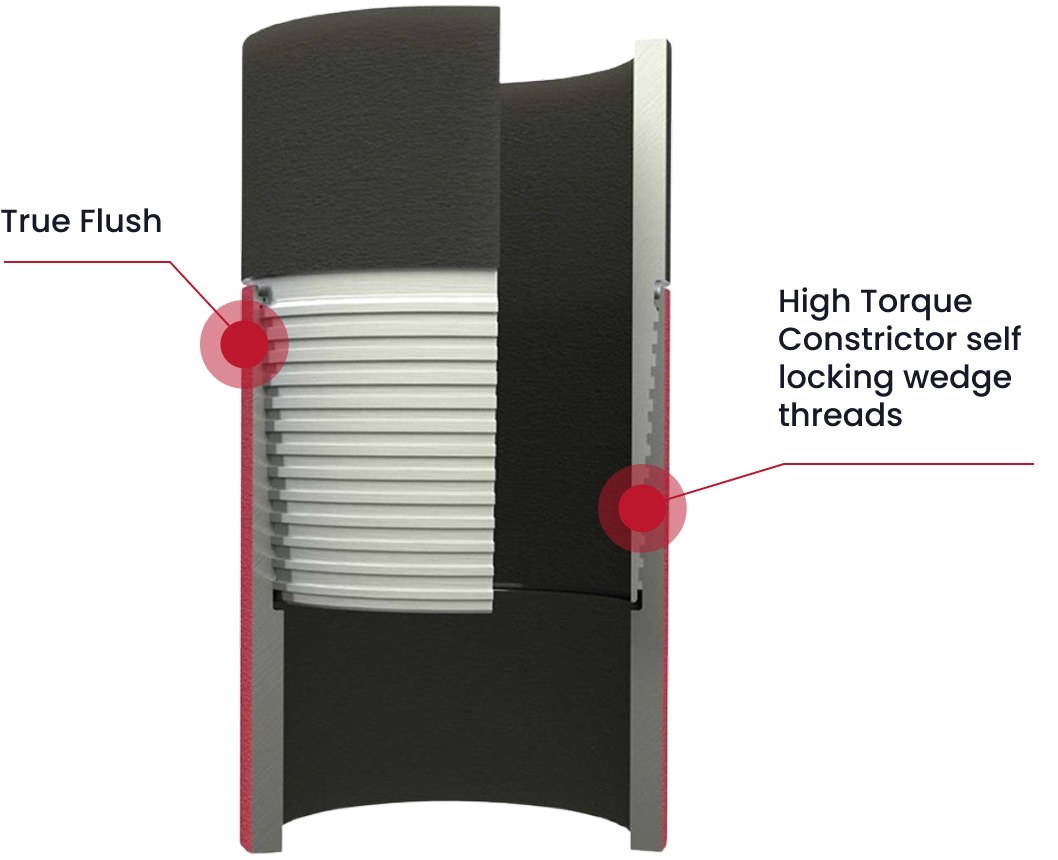

Traditional flush joint connections fall short—low torque, weak tensile strength, and prone to galling. Cobra® SP changes the game.

A leading drilling contractor in Louisiana needed a flush connection capable of drilling through several hundred feet of shale in a high-pressure reservoir. Fermata’s well services team identified the main technical challenges: torque, fatigue, compression, and buckling. After a thorough evaluation, the 7” x 32# P110 HC Cobra™ SP connection was selected for its proven performance in demanding applications.

During casing operations, a non-retrievable drilling shoe replaced the standard float shoe. The Cobra® SP connections made up smoothly with consistent torque-turn profiles throughout the string. Rig crews reported it as one of the fastest and easiest connections they had ever run, even compared to other premium connections.

The string was set at 11,886’ and drilling commenced. The Cobra™ SP connection performed flawlessly, rotating for over 12 hours at 90 rpm. After drilling through the initial 400’ shale target, operations continued for an additional 300’ without issue, placing the well in an optimal position to maximize production.

Result:

The Cobra™ SP delivered reliable torque, fatigue resistance, and compressive strength, enabling efficient drilling and casing in a single run-demonstrating why it’s trusted for challenging flush joint applications

.Metal seal premium connections

Extreme torque – locked thread

Conventional – shoulder torque

Thread sealing semi-premium connections

Thread sealing semi-premium connections

Slim Line

High strength

Reach out to your Fermata™ representative for more information

From casing design to finished OCTG product, we can assist every step of the way!

Contact us and we will consult you in a short time